Quality EPCM

Services for

Western Canada

CDE Engineering Ltd. is a full-service engineering firm based in Calgary, AB, that specializes in providing engineering, procurement, and construction management services for Canada’s energy sector, with a focus on the upstream and mid-stream segments of the oil and gas industry.

At CDE Engineering, safety is our top priority. We have robust protocols in place to ensure that all of our projects are completed safely and without incident. We understand the importance of providing our clients with the best possible value for their investment, and we work hard to ensure that we achieve this without compromising on safety.

Building on our commitment to safety, our team of experienced and highly skilled engineers and designers use the latest technology and industry-proven techniques to deliver high-quality projects that meet or exceed our clients’ expectations. We take pride in our ability to consistently provide outstanding results, and we strive to build long-term relationships with our clients based on trust and service.

Our Approach

At CDE Engineering, we recognize that safety and technical accuracy are of the utmost importance, and we prioritize them in every aspect of our work. However, we also understand that our clients have unique needs and requirements that must be taken into account. We believe in taking a balanced and considered approach that prioritizes safety and technical accuracy, while also ensuring that our clients’ needs and objectives are met. Our team of experienced engineers and project managers work closely with clients to develop solutions that are customized to their specific situation, and we strive to exceed their expectations with every project we undertake.”

Our approach is built on a foundation of technical expertise and knowledge that our key team members bring to every project. We combine this expertise with a philosophy of continuous learning and improvement, staying up-to-date with the latest technologies and industry advancements. Our team of experienced engineers and project managers bring their extensive knowledge to each project, using their skills to develop innovative and cost-efficient solutions. We believe that our people are our greatest asset, and their knowledge and experience are at the core of everything we do at CDE Engineering.

Leadership

Arash Jafarpisheh, P.Eng. | Principal

Arash, a certified professional engineer, has over 15 years of experience in the oil and gas industry. He holds a Mechanical Engineering degree from the University of Calgary and a process piping drafting certificate from SAIT. Arash has worked on a variety of projects, from upstream gathering systems to oil processing batteries and gas plants, providing him with a unique perspective on project planning, design, and construction execution. With extensive experience in project, process, piping, and mechanical engineering, Arash excels in effective communication with clients, coworkers, and suppliers, building strong relationships along the way.

Arash Jafarpisheh, P.Eng.

Principal

Nima Rohani, P.Eng. | Principal

Nima is an experienced electrical engineer in the oil and gas industry with a proven track record of contributing to the successful execution of various projects. His 15 years of experience includes FEED, detailed design, and construction support for a wide range of applications such as gas plants, oil batteries, custody transfer stations, midstream pump stations, pipeline networks, tank farms, chemical plants, and processing facilities.

With extensive knowledge in electrical, controls, instrumentation, and telecommunications, Nima is well-positioned to provide valuable insights and contribute to the successful completion of projects. He has worked with industry clients including major midstream companies and possesses a broad experience in the upstream and midstream sectors. Nima applies lessons learned from his work with various clients to provide innovative and cost-effective solutions to meet project goals.

Nima Rohani, P.Eng.

Principal

Bryan Cawthorn, P.Eng. | Principal

Bryan is a professional chemical engineer with over 15 years of experience in the energy industry, specializing in upstream facilities design, and midstream distribution networks. Bryan has a proven track record in providing unique solutions to challenging and atypical problems facing his clients. At CDE Engineering, Bryan plays a crucial role in projects from initial design to commissioning, providing technical guidance and acting as an interface between CDE’s engineering disciplines to ensure consistent project outcomes. With his extensive experience in the industry and his current role as the Responsible Member for APEGA, APEGS, and EGBC, Bryan is able to contribute to the successful completion of projects while upholding the highest standards of professionalism and engineering excellence.

Bryan Cawthorn, P.Eng.

Principal

Golriz Boorboor , P.Eng. | Project Manager

Golriz is a professional mechanical engineer with a master’s degree from The University of Calgary and over eleven years of experience in the energy industry. Her expertise includes the design and construction of satellites, batteries, disposal/injection facilities, gas plants, and pipelines.

Golriz’s skills encompass multiple disciplines, including project management, process engineering, mechanical engineering, and instrumentation and controls. She has extensive knowledge in project scoping, process simulations, cost estimation, scheduling, regulatory compliance, procurement, control philosophy, and equipment and instrumentation sizing and selection. Moreover, Golriz collaborates effectively with clients, vendors, and colleagues from various disciplines at CDE to develop comprehensive mechanical, electrical, and civil drawings.

Golriz Boorboor , P.Eng.

Project Manager

Max Marchand | Drafting Manager

Max Marchand is an accomplished mechanical designer and leader in design drafting and CAD modelling with over 20 years of experience in the oil and gas industry. He began his career as a millwright, welder, and driller in the Canadian foothills before transitioning to a designer role where he discovered his true passion.

Over the past decade, Max has established himself as a reliable and dependable professional, focusing on efficiency, constructability, and operateability in his designs. He is dedicated to creating designs that promote safe and efficient operations, and his attention to detail has earned him a reputation as a valuable contributor to the industry.

Max’s passion for engineering and his commitment to excellence have driven his success throughout his career. As a skilled and dedicated manager, he supports his team in achieving their goals and ensures that his work reflects his dedication and professionalism. With his extensive experience and expertise in design drafting and CAD modeling, Max is a trusted member of the CDE team and is poised to make a significant impact in the industry for years to come.

Max Marchand

Drafting Manager

Brad Reardan | Design Lead

Brad brings a wealth of experience overseeing and directing the drafting and design teams at CDE Engineering. He possesses the expertise to manage complex drafting projects, ensuring that engineering and design specifications are met while adhering to industry standards and regulations.

As a Design Lead, Brad boasts a remarkable 20+ years of expertise in the oil and gas industry. Over half his professional journey has been dedicated to drafting and design work. This experience has empowered him to make valuable contributions to diverse projects, encompassing FEED, detailed design, and construction in key areas such as mineable oilsands, well pads, oil batteries, natural gas processing, LACT systems, compression, and pipelines.

Additionally, Brad possesses seven years of hands-on field experience, having worked as an apprentice Pipefitter on various pipeline and facility construction projects across Alberta, British Columbia, and Saskatchewan.

Brad Reardan

Design Lead

Richard Joseph, P.Eng. | Project Manager

Richard is a highly skilled project engineer with over 14 years of experience in the oil and gas industry. He specializes in the design and construction of upstream and midstream facilities, with extensive experience in satellite, battery, pipeline, and gas plant projects. As a certified professional engineer with a degree in Petroleum Engineering from the University of Calgary, Richard brings a wealth of technical expertise to his role at CDE Engineering.

Prior to joining CDE Engineering, Richard held Project Engineer positions at various EPCM firms where he was involved in the successful completion of diverse oil and gas projects. With a strong background in project management, process design, and engineering drafting, Richard is a valuable member of the CDE team, contributing to the successful delivery of projects throughout the project life cycle.

Richard Joseph, P.Eng.

Project Manager

Expertise

At CDE, we pride ourselves on our commitment to finding creative, effective solutions to our clients’ most complex challenges. Our experienced team of engineers and designers has a passion for tackling both greenfield and brownfield projects, providing top-notch commissioning and troubleshooting services, and delivering high-quality results in all areas of the energy industry. What sets our team apart is our ability to take an integrated approach to system integration, considering the practical reality of the systems and their upstream and downstream impacts. Our team members specialize in problem-solving and lateral thinking, combined with our technical expertise and ability to collaborate, making us the go-to firm for engineering solutions.

Custody Transfer and Measurement

We understand that precision and dependability are crucial when it comes to custody transfer applications. Our team has built a reputation as a leading provider of comprehensive custody transfer facilities in Western Canada, catering to a wide variety of needs. We have extensive experience with various forms of hydrocarbons, including low vapour pressure and high vapour pressure. Our team is equipped to handle complex applications such as isokinetic flow, automated sampling, and system integration. We have the knowledge and expertise to tackle any challenge and deliver effective solutions.

Product Storage & Terminalling

The production, transportation, and storage of petroleum products are closely connected and essential components of the industry. Our expertise in storage and terminals includes bulk storage, blending, and shipping facilities for various low and high vapour pressure products. We recognize the importance of an integrated value chain, and our team is experienced in designing and optimizing terminal facilities to efficiently connect various aspects of the supply chain, from upstream production to downstream distribution. In addition to our expertise in blending and transloading, we are also experienced in truck loading and offloading operations, as well as other methods of product transport. Our expertise ensures that our clients have comprehensive solutions for all their storage and terminal needs.

Compressor Design & Optimization

At CDE, we have extensive experience in the design and optimization of gas compression systems, with a particular emphasis on reciprocating compressors, screw compressors, and rotary vane compressors for natural gas processing, transmission, storage, and vapour recovery applications. Our team has deep expertise in the complexities of gas compression, including sweet and sour gas compression, acid gas compression, and dense phase compression. In our commitment to delivering comprehensive solutions to our clients, we work closely with a network of industry experts and compressor packagers, leveraging their knowledge and expertise in our designs. This ensures that our clients receive the most innovative and reliable solutions for their gas compression needs.

Natural Gas and Liquid Hydrocarbon Processing

CDE’s process engineering team is highly experienced in designing and optimizing natural gas processing, stabilization, and hydrocarbon fractionation facilities for a wide range of applications. Our expertise includes sweet and sour gas processing, as well as critical sour gas handling for high hydrogen sulphide and carbon dioxide content. We have deep knowledge of various unit operations, such as dehydration using glycol and desiccant systems, shallow cut hydrocarbon dew point processing with mechanical refrigeration, and cryogenic processing. Our team is also skilled in condensate and natural gas liquids stabilization and fractionation. We specialize in both greenfield and brownfield projects, and conduct debottlenecking studies to help our clients optimize their operations. Our goal is to provide comprehensive solutions that meet our clients’ unique needs and challenges.

Pipeline Infrastructure

At CDE, we have extensive experience in the mechanical design of pipelines, adhering to all Canadian codes and specifications for stress analysis and mechanical design. We also specialize in pipeline hydraulics, using the latest industry software to model system hydraulics for both single-phase and multiphase applications. Our team has experience in pipeline control and optimization to ensure that flow and resulting pressure gradients are controlled throughout the system for appropriate and safe operation. We provide comprehensive solutions for pipeline projects, from initial design and regulatory approvals to construction, commissioning, and ongoing operation.

Mainline Centrifugal Pump Solutions

At CDE, we specialize in designing and optimizing mainline centrifugal pump systems for liquid transportation. Our team has extensive experience in the intricacies of control and operation, including complex systems with parallel and series operation, variable frequency control, and integrated control systems. We work closely with our clients to ensure reliable and efficient operation of their pump systems and provide comprehensive solutions for all their mainline pump needs.

Oil Processing Solutions

Our process engineers have expertise in oil processing systems for various upstream production scenarios. We specialize in handling the unique challenges posed by different fluid compositions, including sweet, sour, and high-viscosity oils. Our team is also familiar with high-pressure water disposal applications, water treatment, and solution gas handling. Our team is familiar with all applicable codes and standards with an emphasis on flare emission reduction, and environmental monitoring. Additionally our team has expertise in inlet liquid receiving design to reduce the negative operational impacts of liquid slugging. Working closely with our clients and their operating teams CDE works to deliver consistent and reliable processing solutions.

Power Generation and Integration

CDE’s electrical engineering team has extensive experience in power generation and integration, with a focus on medium and low voltage systems to plant infrastructure. Our team is well-versed in the design and implementation of natural gas-fired power generation, including reciprocating engines and gas turbines. Our team of electrical engineers works closely with our clients to design and optimize power generation systems that are reliable, efficient, and meet their specific needs. We are committed to delivering comprehensive solutions that integrate seamlessly with overall plant infrastructure, ensuring safe and effective operation for years to come.

Project Experience

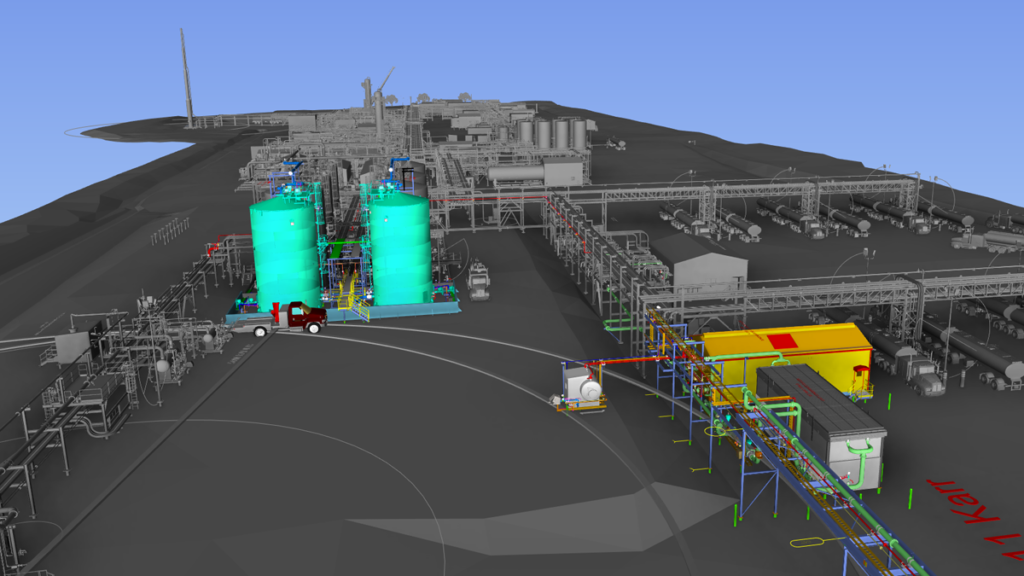

Integrated Gas and Liquids Facility Expansion

CDE played a key role in the expansion of a natural gas, condensate, and water handling facility for a client. Our process engineering team conducted an in-depth HYSYS simulation, considering current, future, and potential process design cases to optimize the facility’s operations. We provided detailed specifications for all major equipment and packages required for the project, ensuring compliance with all relevant regulatory standards. In addition, our team leveraged our expertise in gas and liquid processing to specify the process conditions for critical mechanical equipment such as pumps and compressors. The result was a smooth-functioning facility that met our client’s unique needs and challenges.

Integrated Gas and Liquids Facility Expansion

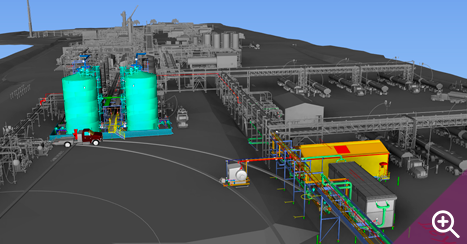

Condensate LACT Interconnect

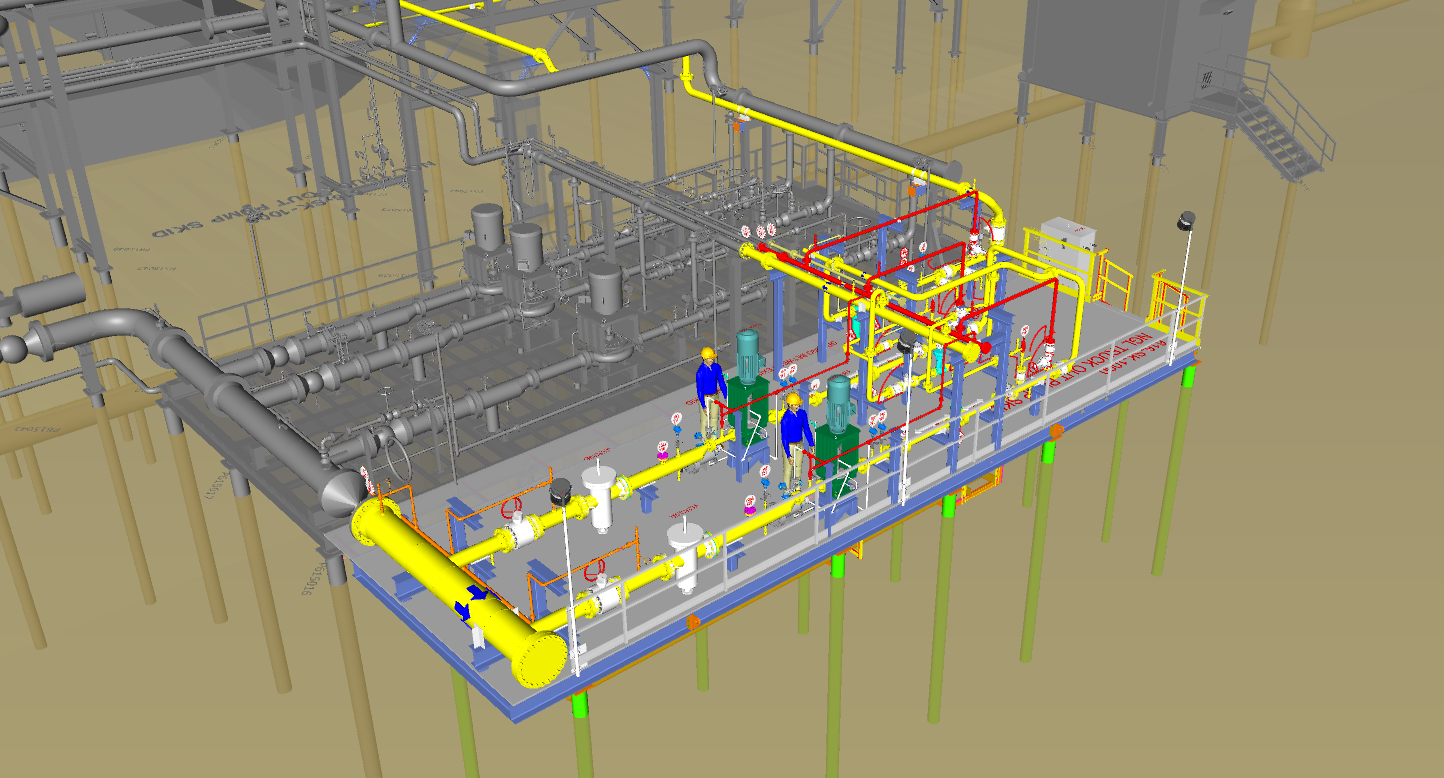

CDE was contracted to design and install incremental product storage, booster pumps, and quality assurance/measurement assurance equipment to connect an adjacent third-party condensate Lease Automatic Custody Transfer (LACT) unit. We executed engineering design to meet all third-party battery limit interface requirement and ensure compliance with the current, future, and potential process design cases. Our team also specified all associated electrical and controls infrastructure to provide our client with a reliable, efficient, and accurate interconnect system.

Condensate LACT Interconnect

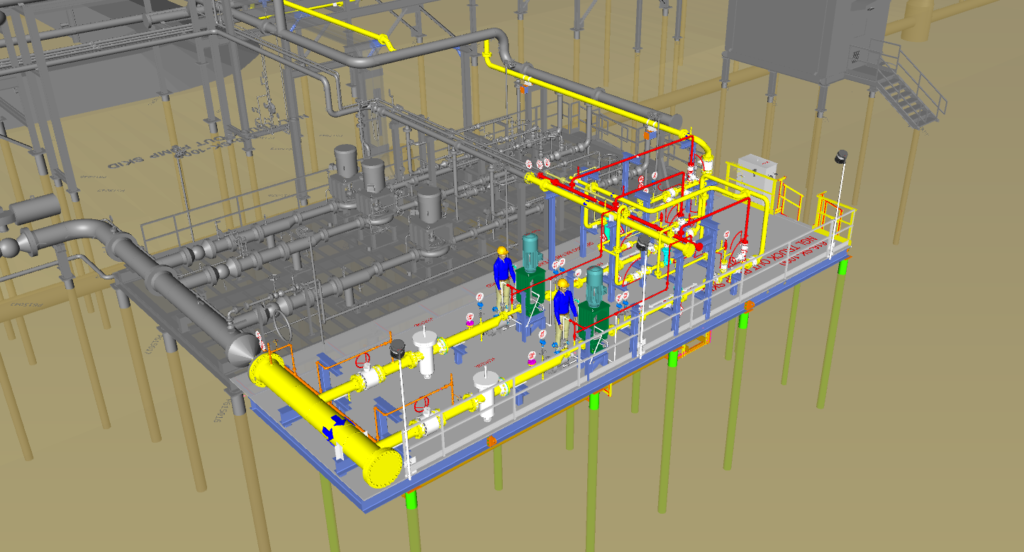

NGL LACT Interconnect

CDE was contracted to design and install booster pumps, as well as quality assurance equipment, to connect an adjacent third-party natural gas liquids (NGL) Lease Automatic Custody Transfer (LACT) unit. Due to the high vapor pressure of the NGL product, our team conducted detailed fluid hydraulics analyses to ensure reliable and safe operation of the rotating equipment throughout the plant lifecycle. We executed an engineering design that met all third-party battery limit interface requirements and ensured compliance with the current, future, and potential process design cases. Our team also specified all associated electrical and controls infrastructure, providing our client with a reliable, efficient, and accurate interconnect system.

NGL LACT Interconnect

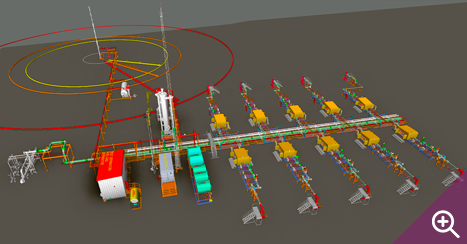

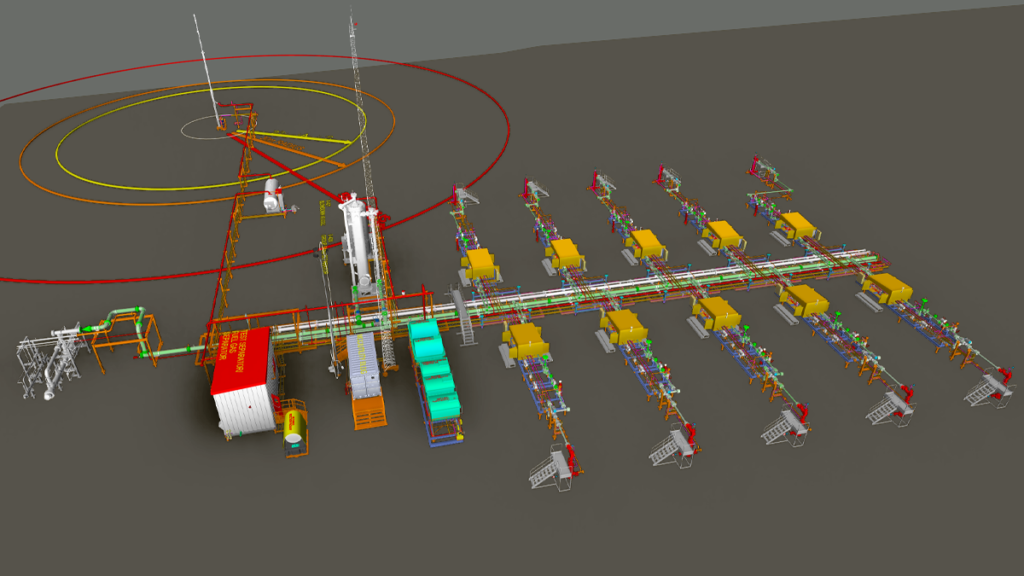

Montney Well Pad Standardization

CDE worked closely with our client to design a standardized well pad that would increase consistency, reduce construction time and costs, and improve overall safety. Our team conducted thorough facility design and assessments to ensure compliance with all regulatory requirements, while also taking into account current and potential process design cases. The result was a high-quality, efficient well pad design that was subsequently replicated across the client’s operations to maximize operational effectiveness and cost savings.

Montney Well Pad Standardization

Montney Well Pad Equipment Optimization

As an extension of CDE’s standardized approach to a client’s Montney well pad design CDE was contracted to consider further optimizations to reduce equipment on site. We successfully completed a revised version of this project that involved the removal of individual wellhead de-sand separators and the implementation of a single group de-sand separator, leading to potential reductions in operational and construction costs, increased safety, and a more streamlined facility design.Montney Well Pad Equipment Optimization

NGL Offloading Infrastructure Design and Coordination

CDE was contracted to complete design of natural gas liquids offloading infrastructure in response to a short-notice client request. In addition to rigorous client specifications and governmental requirements for custody transfer the project required coordination with multiple parties to ensure successful stakeholder engagement in an extremely expedited project. With stakeholder alignment in place the project was executed smoothly and efficiently within five days of inception.

NGL Offloading Infrastructure Design and Coordination

Technology

At CDE Engineering, we understand the importance of utilizing the most advanced and reliable tools in the industry. This necessitates the employment of the most sophisticated and dependable software technologies available. With these tools at our disposal, our team is well-equipped to handle even the most complex engineering projects, from project planning and design to implementation and commissioning. We make it a priority to stay up-to-date with the ever-evolving demands of our clients, continuously researching and investing in new technologies. Our commitment to innovation and excellence allows us to deliver cutting-edge solutions that are both cost-effective and sustainable.

Autodesk

AutoCAD

Navisworks

Maya

Recap

Plant3D

Fusion

Thermon

Computrace Design Suite

AspenTech

HYSYS Process Simulation

Etap

Fault Studies

Load Analysis

Protection Coordination

Oracle

Primevera

Hexagon

CADWorx

Caesar II

Intertek

Light From Modeler

Schlumberger

PIPESIM

PVSYST

Photovoltaic Software

Leica

Truview

ABAQUS

FEA

Microsoft

Microsoft Project

We're Hiring!

CDE Engineering Ltd. is seeking talented professionals who are passionate about their work and committed to supporting and developing their fellow team members. Our team culture is built on mutual respect and professionalism, and we strive to create a positive and collaborative working environment where everyone feels valued and supported. Our team members are dedicated to delivering high-quality solutions that meet the unique needs of our clients. By fostering a culture of teamwork and continuous learning, we work together to achieve our shared goals and consistently exceed client expectations.